Our Mission

To be the providers of technologies, strategies and services, which delivers long term benefits based upon our clients key business requirements. The strategies evolved should be economical, efficient, durable, and flexible and allow the organizations to respond rapidly to both market and customer’s needs.

Extreme Quality

DAS Valves Est. to implement TQM Philosophy by documenting its quality system and pinpointing on continuous process improvements. Company is to have developed QA/QC manuals on otherwise highly ignored yet subdivisions of industrial construction i.e. industrial maintenance and other related jobs.

Our Approach

To move towards our targets of Zero- defects & Zero- accidents at site. Total quality/ Technical/ Non-technical management with aim to acquire higher ISO- certifications. Extension to our activities to neighboring and to enter international joint venture.

Exclusive Support

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus cursus lectus vel pellentesque. Etiam tincidunt.

Welcome to DAS

DAS Valves Services is full industrial service commercial marketing its services in the KINGDOM OF SAUDI ARABIA among commercial, industrial & institutional clients. We have evolved into a full-service construction firm with its Headquarter located in Khobar City, Saudi Arabia. It was created with the specific goal of providing engineering and consulting industrial services while, at the same time, Providing each individual client with a positive services experience.

Moreover, the company provides a variety of services to the other industries in terms of understanding the potential opportunities in the market as a strategic plan. This was the opening gate for the starting of ” DASVS” projects in the Oil and Gas industry, Energy, Mining and other metal industry. According to this new market, the company set out to establish the technic Construction & Maintenance Manufactory. This Manufactory has been having capability and potential for, installing and maintenance of industrial and technological structures, pressure vessels, equipment and machines related to heavy industry.

The others company Capabilities can be consisted as follow:

- Expand its industrials services involving with the ever changing in the market including valve manufacturing, spare parts, engineering services construction management and program management.

- The Expansion of modernization, industrial automation and signaling.

- Make agreements with international companies in the world for off shore & on shore projects

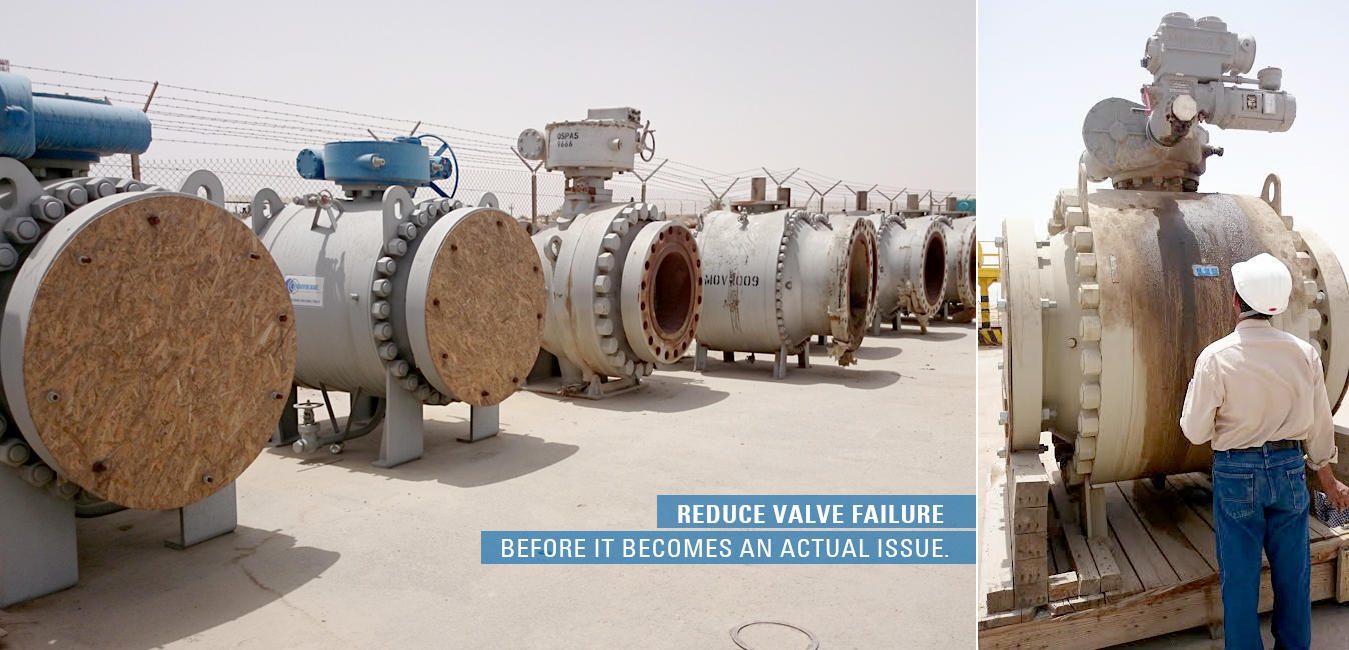

On-Line Valve Maintenance

Emergency Valve Sealing Services,

Routine Valve Maintenance,

In-Line & Under Pressure Troubleshooting

Valve Maintenance

Specialized in valve drying after valve hydrotest and preservation by using special methods, tools, materials and technique of valve preservation

Consultation

Using our expertise when planning and commissioning your pipeline project will guarantee a smooth and problem free start-up with no valve leaks

Valve Training

We are international certified to train and certify valve technicians to be able to maintain the valve while it is in service.

Emergency Valve Sealing Services

Our techniques and procedures allow technicians to inject cleaner and sealant while the valve is in-line and under pressure.

Valve & Actuator Repairs

Valves that have been in service for a long time can be refurbished and repaired, while the valve is in-line and under pressure.