On-Line Valve Maintenance

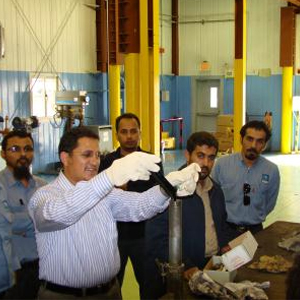

Our techniques and procedures allow technicians to inject cleaner and sealant while the valve is in-line and under pressure. With our expertise and special materials and tools, we are capable to seal the following critical valve components:

- Leakage across the seats

- Stem / Trunnion leakage

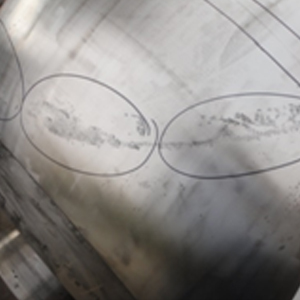

- Valve body leakage

- Valve fitting leakage

- Bonnet leakage

A pressurized pipeline is an extremely dangerous environment to perform valve maintenance around. Experienced valve technicians are trained to fear and respect the extreme pressures associated with pipeline operations. Skilled technicians use on-line pressure to their advantage when diagnosing and resolving leaks.

We are specialized and capable in resolving and implementing the following tasks:

- Emergency Valve Sealing

- Seized / Hard-to-Turn Valves

- Internal Seat Leakage

- Steam Leakage

- Orifice Fitting Leakage

- Body Leakage

- Flange Leakage

- Launcher / Receiver Leakage

- Actuators & Controls

Valves are the most common mechanical device found at any plant, platform or pipeline operation and require routine maintenance to ensure they operate and seal properly every time. Well-maintained valves can potentially operate efficiently for the lifespan of the facility. Following steps are mandatory to be part of routine valve maintenance:

- Lubricated Ball, Plug & Gate Valves

- Actuator and Gearbox Maintenance

- Testing Seat Sealing Integrity

- Topping up the seat sealant system

- Inspecting for leakage to atmosphere, external corrosion

- Draining water from the body cavity, actuator hydraulic system

- Adjusting the stops and/or ball/gate position as needed

- Line break control re-verification and calibration

Get in Touch

Contact Us

DAS Valves Services

- Corporate Office

- Location: Saudi Arabia, Eastern province,

Al-Khobar, King Abdullah Street - cross #4 - Phone: +966 13 893 4420

- Fax: +966 138934420

- E-mail: dhaferalshehri@ymail.com